MANUFACTURING

AeroTEC’s AS9100D certified manufacturing facility is located at the AeroTEC Flight Test Center (AFTC) in Moses Lake, WA where they offer fabrication & assembly services, build-to-print manufacturing, and provide support to flight test programs with the design and manufacturing of experimental test components and flight test equipment.

We utilize Siemens NX CAD/CAM software that allows us to design, program and validate our CNC machined parts.

MANUFACTURING

AeroTEC’s AS9100D certified manufacturing facility is located at the AeroTEC Flight Test Center (AFTC) in Moses Lake, WA where they offer fabrication & assembly services, build-to-print manufacturing, and provide support to flight test programs with the design and manufacturing of experimental test components and flight test equipment.

We utilize Siemens NX CAD/CAM software that allows us to design, program and validate our CNC machined parts.

AS9100D CERTIFIED MANUFACTURING

The 14,000 sq ft AeroTEC Manufacturing Center is ISO9001/AS9100D certified, serving the commercial and military aerospace industry. We pride ourselves as a provider of high-quality manufacturing and assembly solutions.

CAPABILITIES

- CNC machining (3, 4 and 5-axis)

- CNC router (3-axis)

- Sheet metal fabrication

- Complex aerospace assemblies

- Production of sub-assemblies

- Wire shop & wire harness fabrication

- Out of autoclave (OOA) composites

- Composite tooling fabrication

- Priming & painting capabilities (72″ x 96″ x 120″)

- Onsite batter servicing, maintenance and overhaul

- 3D printing

- Welding & fabrication

METALS

AeroTEC’s Manufacturing Center works with a variety of materials, depending on what your project needs, from basic metals like aluminum to more difficult materials like steel.

- Aluminum

- Steel (Mild, Carbon, Stainless)

- Titanium

- Composites

- Fiberglass

EQUIPMENT

- OKK VC-X500 Simultaneous 5 axis (24″ x 27.5″ x 33.5″)

- Doosan DNM 5700 3 & 4 axis (20″ x 22″ x 41″)

- Doosan DNM 750II 3 & 4 axis (25″ x 30″ x 64″)

- GMR 512 CNC Router 12’ x 5’ Bed (20″ x 60″ x 120″)

- Dukin MHB CMM (CMM Manager Software)

- Haas VF4SS high speed 3 & 4 axis (20″ x 25″ x 50″)

- Haas VF11 large format 3 & 4 axis (25” x 38” x 100”)

- HAAS TL2 (8″ x 48″)

- Shop PRS alpha 120-60-8

INSPECTION

AeroTEC has a variety of manufacturing inspection systems in place to make sure your products are precise, accurate and thoroughly tested.

- NDT Inspection

- Liquid fluorescent penetrant bench

- UT Equipment

- FAI Inspection

- CMM

- FARO arm 3D laser scanner

- Granit surface plate and certified hand measurement equipment

EXPERIMENTAL MANUFACTURING CAPABILITIES

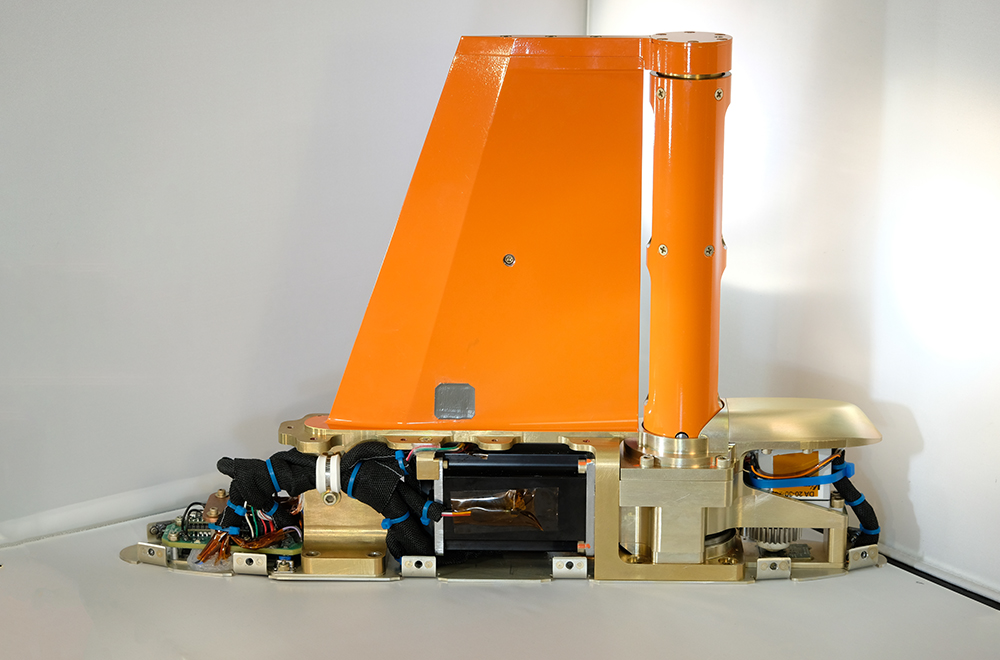

SPECIAL TEST EQUIPMENT MANUFACTURING

Rapid design and build of complex test equipment including ballast systems, trailing cone wheel assemblies, hot fuel rigs and load alleviation systems.

PROTOTYPING

With engineers onsite working closely with manufacturing technicians, AeroTEC is able to design solutions for troublesome parts and rapidly build airworthy replacements.

RAPID FABRICATION

Onsite fabrication of test parts and manufacturing of replacement hardware provides quick turn solutions that keep test programs in the air instead of on the ground waiting for parts.

ADDITIVE MANUFACTURING

3D Printing using ABS, PLA, Nylon, Polycarbonate and flexible materials