ENGINEERING TOOLBOX

AeroTEC takes a model-based approach to our engineering design, leveraging Siemens Teamcenter to manage the entire product lifecycle and maintain configuration control. As our team performs design, analysis, and simulation work, the resulting data sets are stitched together and integrated through Teamcenter so they can be shared across departments such as manufacturing, quality, and supply chain.

ENGINEERING TOOLBOX

AeroTEC takes a model-based approach to our engineering design, leveraging Siemens Teamcenter to manage the entire product lifecycle and maintain configuration control. As our team performs design, analysis, and simulation work, the resulting data sets are stitched together and integrated through Teamcenter so they can be shared across departments such as manufacturing, quality, and supply chain.

Integrated toolbox to maximize data flow

We use a heavily integrated toolbox to maximize data flow through our processes and compress our design to manufacture cycle times. Leveraging the latest in cutting-edge tools, we are able to simulate, model, analyze and manufacture in a way that maximizes value for our customers and protects overall program objectives. Digitally threading our metadata throughout the process removes redundancy or repetition and ensures a consolidated design that is fit for manufacture and flows through the process rapidly.

Following the latest developments in Model Based Systems Engineering (MBSE) and using the latest tools to design in Model Based Definition (MBD) methodologies enables truly unique, fit-for-purpose and optimized solutions that ultimately yield schedule and cost compression opportunities.

OUR TYPICAL PROCESS

Captures requirements to ensure production application fit

Models 3D spaces, capturing MBD/PMI data in the process

Leverages parametric and feature-based design to allow rapid iteration

Converts 3D models into manufacturing data

Simple inspection of conformity to design intent

Highlights opportunities for design optimization

Requirements Management

Good requirements management is the start to any detailed design program. AeroTEC uses JAMA, a tool that centralized aircraft, system, and component level requirements. We’ve even built our own propriety ALR, SLR, and DLR reference libraries within JAMA for Part 25, 25, 27 and 29 projects. AeroTEC has also worked with IBM Doors as a requirements management tool to support customers that prefer utilize Doors.

Simulation & Analysis

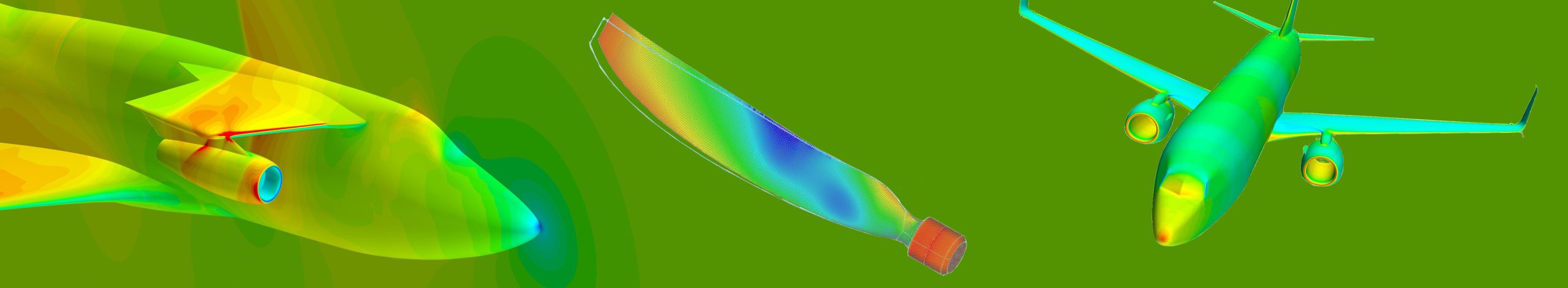

Simcenter STAR-CCM+ for Computational Fluid Dynamics (CFD)

AeroTEC uses Star-CCM+ in all types of fluid dynamic analysis problems ranging from low-speed, high lift design cases to high-speed flow regimes including external and internal flows.

FEMAP with NX NASTRAN for Finite Element Analysis (FEM)

AeroTEC has extensive experience using FEMAP with NX Nastran for primary and secondary aircraft structural design and a wide variety of applications across FAR part 23 and 25 development programs. Tools are used in conjunction with STAR-CCM+ for the prediction of aerodynamic internal or external loads and applied to static and dynamic solutions.

AMESIM for Integrated Digital Systems Modeling

1D simulation for Systems Modeling with the ability to tie to almost any other tool for detail component models as needed. AeroTEC uses Amesim to provide in depth systems integration modeling for performance and failure mode testing. Can be using in a variety of ways to model systems at a basic or high level down to a detailed systems performance analysis when needed.

NASA LEWICE for Ice Accretion Analysis

2D and 3D ice accretion tools for surface ice accretion development. AeroTEC uses LEWICE in concert with STAR-CCM+ for aircraft deice system design and analysis for FAR part 23 and 25 aircraft certification requirements.

RELEX & NASGRO for Fault Tree Analysis

Fault tree analysis software allows our team to construct a graphical representation of issues and contributing events and helps them analyze risk and reliability solutions. For structural issues like fatigue and cracks, we use NASGRO to calculate stress intensity factors and critical crack size.

DFMEA for Design Failure Modes Analysis

DFEA helps engineers analyze potential design problems and the significance of their impact early in the design process so that failures can be corrected early.

DESIGN TOOLBOX

NX CAD & CAM

3D CAD Design, Drafting & Manufacturing Support

NX is the primary CAD system used for 3D modeling and manufacturing. NX ties in with Teamcenter to provide AeroTEC with a world class design software that allows us to move quickly and collaborate efficiently with a wider team of engineers, designers and manufacturing facilities.

NX is used to provide a basis for engineering design work, Model Based Design/Engineering, machine tool programing, engineering data releases (drawings and EWIS).

CATIA

3D Design & Drafting

Design CAD tool used for 3D modeling and interfacing with our customers that utilize CATIA as their primary CAD tool.

GEOMAGIC & POLYWORKS

OML & IML Scanning

AeroTEC uses the two best in class software tools for reverse engineering and inspection to provide the best possible results for the lowest cost. AeroTEC uses Geomagic to reverse engineer any part or surface needed to aircraft modifications or development of parts and hardware.